登陆成功…�?/p>

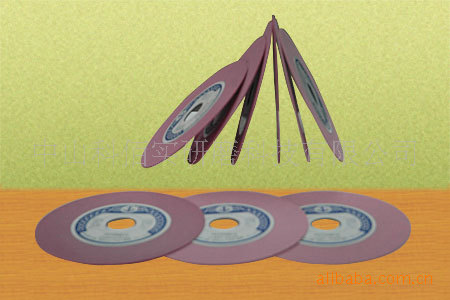

PA120N1A 150*1.6*25.4

PA120N1A 150*1.6*25.4

PA120N1A 150*1.7*25.4

PA120N1A 150*1.8*25.4

均有大量现货,量大从优,欢迎同行前来批发

我司优势批发供应台湾砂轮,诺顿砂轮,金刚笔,无心磨刀板,尼龙轮,切割片等研磨材料,并设有刀具部门,一级代理韩囼�/span>KORLOY刀粒,京瓷刀粒,三菱刀粒,台湾LV铣刀广东总代理,日本STK铣刀广东总代理,欢迎来电询价,联系人:施小姏�/span>13790727441,敬请浏览

| 订购指南 精工细琢 专业品牌 | ||||||||||||

| WA | 46 | K | 5 | V | 5 | A | 350x40x127 | |||||

| 磨料 | 粒度 | 结合剁�/td> | 组织叶�/td> | 制法 | 型状 | 缘形 | 尺寸(DxTxH) | |||||

| 磨料粒度: | Grit | |||||||||||

| 精度是用来表示磨料颗粒几何尺寸的大小,其选择 | Grit is designated to represent the geometrical size of | |||||||||||

| 依据主要是加工工件所需要的表面粗糙�?同时也需 | abrasive grain.The grit size is chosen for customer s | |||||||||||

| 考虑其他一些因�?以外圆磨为例,常用粒度与表靡�/td> | required surface finish as well as other conditions.For | |||||||||||

| 糙度有下面的大致关系: | example,in cylindricai grinding,there is relationship | |||||||||||

| between grit and surface finishes listed as bellow; | ||||||||||||

| 粒度 | 36-46 | 54-60 | 70-80 | 90-100 | Grit | 36-46 | 54-60 | 70-80 | 90-100 | |||

| 粗糙�?/td> | Ra 1.6 | Ra 0.8 | Ra 0.4 | RA 0.2 | Finish | Ra 1.6 | Ra 0.8 | Ra 0.4 | RA 0.2 | |||

| ●粗料度的磨料适用于磨剉� | ●Use Coarse Grit: | |||||||||||

| 1)材质较软,延伸率大以及类似软铁和有色金属等 | 1.for soft,ductile,stringy material such as softsteel | |||||||||||

| 材料 | and nonferrous material | |||||||||||

| 2)进给量大,磨削速度要求高的场合. | 2.for rapid stock removal,high grinding speed | |||||||||||

| 3)表面粗糙度要求不高的场合. | 3.where finish is not important | |||||||||||

| 4)磨削接触面大的场�? | 4.for large areas of contact | |||||||||||

| ●细粒度的磨料适用于磨剉� | ●Use Fine Grit: | |||||||||||

| 1)硬度较高以及类似高碳工具�?硬质合金钱类的金 | 1.for hard,brittle materials such as hard tool steels, | |||||||||||

| 属材料和玻璃等脆性材�? | cemented carbide and glass. | |||||||||||

| 2)表面粗糙度及精度要求高的场合. | 2.for fine finishes | |||||||||||

| 3)磨削接触面小的确场合. | 3.for small areas of contact | |||||||||||

| 4)工件半径或弧度小的场�? | 4.for holding small corner radii | |||||||||||

| 硬度: | Grade: | |||||||||||

| E F G H I J K L M N O P Q R | E F G H I J K L M N O P Q R | |||||||||||

| �?---------------------�?/td> | Soft------------------Hard | |||||||||||

| 砂轮的硬度是指磨料之间的结合�?砂轮中结吇�/td> | The grade indicates the relative holding power of the | |||||||||||

| 剂量的多少决定了砂轮的硬度大�?用户需根据其�/td> | bond which holds abrasive grains in a wheel.ln general, | |||||||||||

| 本的磨削(如进刀�?粗糙�?材质)要求来灵活逈�/td> | with a given type of bond it is the mount of bond which | |||||||||||

| 择砂轮的硬度. | determines a wheel s should select the grade of a wheel | |||||||||||

| 一般砂轮硬度选择的原则是: | based on the grinding parameters such as feed rate. | |||||||||||

| finish requirements,materiials i.e..The following rules | ||||||||||||

| should be followed with regard to grade | ||||||||||||

| ●较软的硬度 | ●Use Soft Grade: | |||||||||||

| 1)进刀量大的粗�? | 1.for rapid stock removal | |||||||||||

| 2)磨削接触面大的场�? | 2.for large greas of contact | |||||||||||

| 3)材质较硬的工�?如高硬度工具钢和硬质合金钢等. | 3.for hard materials such as hard tool steels and carbide. | |||||||||||

| 4)工件抗热性能�?严防表面烧伤和磨�? | 4.for heat sensitive workpieces and grinding can not has | |||||||||||

| burning and discoloration on surface | ||||||||||||

| ●较硬的硬度 | ●Use Hard Grade: | |||||||||||

| 1)进刀量小的精�? | 1.for fine finish with little feed | |||||||||||

| 2)延长砂轮寿命. | 2.for longer wheel life | |||||||||||

| 3)材质较软的工�? | 3.for soft materials | |||||||||||

| 4)磨削接触面小或窄的场�? | 4.for small or narrow areas of contact | |||||||||||

| 组织叶� 5 6 7 8 9 10 11 12 13 | Structure: | 5 6 7 8 9 10 11 12 13 | ||||||||||

| �?-------------- 疎�/td> | Close------------Open | |||||||||||

| 组织号用以表示砂轮内相邻的磨料颗粒之间的跜�/td> | The structure number indicates the space between neighboring | |||||||||||

| 离也就是间隙的大�?砂轮中磨料颗粒所占的体积白�/td> | grains which can also be called grain spacing in a wheel The | |||||||||||

| 分比,也就是其浓度的大�?决定的砂轮的组织�?陵�/td> | volume percentage of abrasive grains which represents the | |||||||||||

| 瓷砂轮组织号变化范围一般是�?�?3,数字越小�?/td> | density of grain in a wheel determines the structure number | |||||||||||

| 示砂轮组织越�?数字越大表示砂轮组织越疏�?练�/td> | of a wheel.The structure of Vitrified sheels ranges from 5 to | |||||||||||

| �?1,12�?3通常是指气孔砂轮. | 13.The smaller the number,the more closed structure the wheel | |||||||||||

| The large the number,the more open structure wheel The numbers | ||||||||||||

| 11.12.13normally indicate porous wheels. | ||||||||||||

以上是关亍�b>【大量现货】砂轮厂磨锯片专用砂轮片的详细介绍,产品田�b>中山科佰实研磨科技有限公司为您提供,如果您寸�b>中山科佰实研磨科技有限公司产品信息感兴趣可�?a class="checkContactWay" href="">联系供应啅�/a>,您也可以查看更多相关的产品�?/p>

施晓纡�span>女士(业务经理)

13790727441

公司电话�?86 0760 22826911

公司传真�?086 0760 22826912

联系我时务必告知是在114批发网上看到的!

免责声明9�/span>以上信息由会员自行提供,内容的真实性、准确性和合法性由发布会员负责�?14批发网对此不承担任何责任�

友情提醒9�/span>为规避购买风险,建议您在购买相关产品前务必确认供应商资质及产品质量�